he firefighting effectiveness of water is directly proportional to its surface area that comes into contact with fire. Due to the microscopic droplet size (50 to 65 microns) achieved with this new technology, the surface area of the water is greatly increased. Greenmist™ extinguishes fire mainly by cooling (heat absorption), oxygen displacement (inert gasses form as water expands at a ratio of 1750 to 1 when converting to steam) and the attenuation of heat transmission/radiation. The electrical resistivity of the de-ionized water agentis at least 1MΩ/cm as required by NFPA 10, allowing it to be listed for Class “C” applications.

GreenMist™ Handhelds

Extinguisher functioning

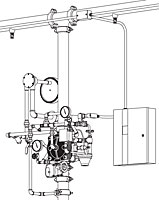

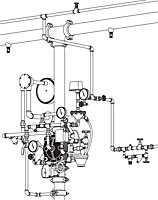

The cylinder is filled to 60% – 72% capacity with de-ionised water and then pressurised with Nitrogen to 15bar at 20°C.

Inside the cylinder there is a ‘double tube’ arrangement with a unique rotor attached to the tubes, at the bottom of the cylinder.

Upon activation (squeezing the top lever down) Nitrogen is forced down the smaller inner tube (air tube) via specially designed holes, to supply compressed gas to the rotor. Simultaneously, Water is delivered at the same pressure to the rotor. This causes the mechanism inside the rotor to spin and as a result, generates a mixture of compressed Nitrogen and Water in a piston method.

The centrally positioned tube (water tube) connects the rotor to the valve outlet and transports the mixture of water and gas to the mist generating nozzle at the end of the hose.

The pressurised mixture of water and gas is forced through the atomising holes in the nozzle so that the water streams collide, generating a dynamic stream of extinguishing mist.

The GreenMist™ product range consists of standard three and six -litre handheld extinguishers in water and foam.

Benefits

- Safe for people – no toxicity or thermal breakdown

- 100% eco-friendly – no environmental impact

- All-in-one extinguisher – Extinguishes Class A, B, C and F fires

- Cooling effect – reduces temperature rapidly

- Mist blanket – shielding from radiant heat

- Good visibility during discharge – compared to CO₂ and dry powder extinguishers

- Safe on equipment – no thermal or static shock

- Safe on electrical fires

- Economic agent – relatively inexpensive compared to other extinguishing agents

- Readily available agent – in adequate quantities under most circumstances

- Easy to refill – only requires de-ionized water and nitrogen

- Small amount of water used to extinguish fire – compared to normal Class A extinguishers

- Zero or little cleanup required – compared to dry powder extinguishers

- Stainless steel cylinder – corrosion resistant

- Minimal training – easy to use, maintain and service

- Confident selection by staff – no need to chose between various extinguishers